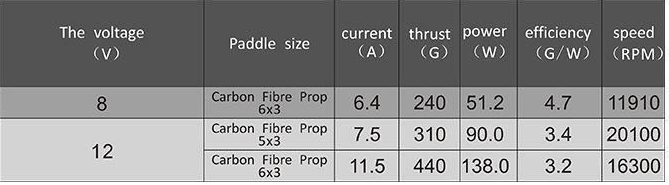

This small guide is to help you choose the right motor for your quadcopter or other multirotor. To help you with this decision, it would be desirable to have several test statistics at your disposal which can be found in the thrust data tables. Luckily, reputable manufacturers will have carried out these necessary tests so you don’t have to and these will provide you with the needed information. An example of one such thrust data table for a MT1806 is given below:

If you are totally unfamiliar with brush-less motors, its a good idea to quickly read our beginners guide to brushless motors

Where to start?

Knowing the weight of your multiorotor is the first thing we need to know. When you are building, or planning your next drone build knowing the exact weight can be difficult. However you will need to start somewhere and as choose and change components you can slowly refine the weight estimation.

I like to start by first knowing what frame I am going to use, as that gives some restrictions on the maximum motor or propeller size. Most frames that you can buy will also give you some recommendations as to what motors you should use to give you an idea of what to look for. I will also then add the weight of the camera and gimbal I want to use.

Thrust to weight ratio

With multi rotors its important to make sure that your motors can produce around 50% more thrust than the total weight of your drone. Or in other words your drone should be able to hover at just over half throttle. This is an important rule to follow is it means that you motors will have enough extra thrust to control your multi-rotor in wind and during aggressive flight maneuvers. If you are always going to by flying gently and smoothly increase the weight so that you hover at around 70% throttle for a less responsive drone. So if your total weight of your quadcopter is 800g, your motors on a quadcopter will need to produce 1.6Kg of thrust in total, or 400g max thrust per motor.

For miniquad racing, you would want a very agile quadcopter, so having a much higher thrust to weight ratio is desirable, but for an aerial photography drone that we will be flying gently, you could get away with lower power to weight ratios, but in general I would say that you should plan your build at around a 2:1 power to weight ratio, as you can always use the extra remaining weight to add bigger batteries to fly for longer.

Worked Example - A rough weight estimation

Lets say we want to build the miniquad as described in this silver blade miniquad build guide. We will start by deciding what frame we want to use, and in this case its the silver blade 37. The product description suggests we use an 1806-2204 size motor so by looking around on the internet we can get an average weight of this class of motors which is around 100g (which is actually abit of an over estimation). Simiarly 3-4S Lipo batteries that are around 1300-1800mah are commonly used with miniquads so we will base our battery weight on that size. The summary of the weight estimation is shown below, remember this is just a very rough estimate that we start with.

- Flight Controller - 15g

- R/C Receiver - 15g

- Silver Blade Frame - 150g

- 4x Motors and ESC - 200g

- 3S LiPo Battery (1300-1800mah) - 150g

- FPV Camera and Transmitter - 50g

So the weight of our drone will be around 680g so we need to have motors that can produce at least two times the amount of thrust in total (1.2Kg of thrust in total), however if they can produce more we will probably be able to fly faster. Since we are building a quadcopter, each motor must product at least 300g of thrust each.

If you do find this process particularly hard the best place to start is to look around a dronetrest, or the internet for other drone pilots who have shared their information on a drone build similar to yours, you can then base your weights on the parts they used. Or you can always ask for some help and advice on our help section

Reading that data

Based on our weight estimation we know we need to find a motor capable of producing a maximum thrust of 300g each, By inspecting the thrust tables of each motor you will gradual find a few motors that have the required thrust performance. In this case we have come across the data for the MT2204 motor which looks promising.

If you find it hard to know where to start, the best thing is to find a build guide, or quadcopter similar to the one you are building so see what motors and other equipment was used that you can use as a starting point.

Checking the thrust

Now we can get on with investigating and extracting useful information from a table such as the one above to find our quadcopter motor. We can see that this manufacturer has tested this motor with two different voltages (2S (approx 8V) and 3S (approx 12V) battery), and a number of different propellers (called paddles in the above table ![]() ). We are then given the amperage that the motor pulls, the thrust that it produces and the efficiency (thrust in grams/power in watts), as well as some other information. We can see from the table that with a 3S battery, these motors will produce enough thrust with 5x3, or 6x3 propellers which produce more than the required 300g each.

). We are then given the amperage that the motor pulls, the thrust that it produces and the efficiency (thrust in grams/power in watts), as well as some other information. We can see from the table that with a 3S battery, these motors will produce enough thrust with 5x3, or 6x3 propellers which produce more than the required 300g each.

Comparing the efficiency

So, the first port of call is arguably investigating the thrust produced by the motors. To further differentiate between motors, it is my belief that efficiency should next be considered. The efficiency is commonly expressed as the thrust divided by the power used in watts or g/W. The more efficient a motor is (or the bigger the g/W number is), the longer the copter will fly. A general rule of thumb would be anything over 7 for efficiency is good, and of course, the higher the value the better. Some of the larger motors (BE 8108) have an efficiency (g/W) of over 18!

Once you have found several motors that produce the required level of thrust an easy way to choose the best one would be to get the most efficient one, but this will also usually end up being the most expensive one.

However, as mentioned previously in this article, this may not be your priority. You may want small, agile copter for acrobatic moves in the air, in which case you want high rpm, and the efficiency will necessarily take a hit which is usually the case for high KV motors. In our example we are choosing a motor for a miniquad, so the type of motor you would use for these copters is one like the MT2204, the table of which is shown above. This is why the efficiency of this motor is relatively poor.

Matching an ESC to your motor

Now that we have confirmed that this motor is suitable for our application, we look at the Amp draw for our chosen motor/battery/propeller. In our case, this is maximum of 7.5A for a 5x3 prop, and 11.5A for a 6x3 prop. Since in our build we chose the 5x3 propellers, so we will need to use an ESC that is rated over 7.5A, so an 12A ESC would be a good choice for this motor/propeller running on a 3S battery.

Refine the weight estimate to choose a battery

Now that you have chosen some components you will be able to update the initial weight estimate as we have actual weights of components. Based on these motors producing a max thrust of 310g with 5x3 props, our quadcopter should weigh less than 620g. The actual weight of all the electronics and the quadcopter frame come to 368g so that means we can get a battery up to 250g in weight. If you find that you dont have enough weight left over for a decent size battery you might want to go back and choose larger motors, or use larger propellers.

Instead of using all the remaining weight for a battery, a slightly lighter battery at 160g (tattu 3S 1800mah) was used so that our quadcopter will have more agility for racing. The actual brand will depend on your preferences and budget, but for more information you might want to check our LiPo battery buying guide

Hope that helps you when it comes to choosing a motor for your drone. If you have any questions please let me know. If you want some advice before buying anything you can also ask on dronetrest and myself, or someone else will be more than happy to give you some suggestions ![]()

This article was co written by Alex (@unmannedtech) and Sam (@SamBot)